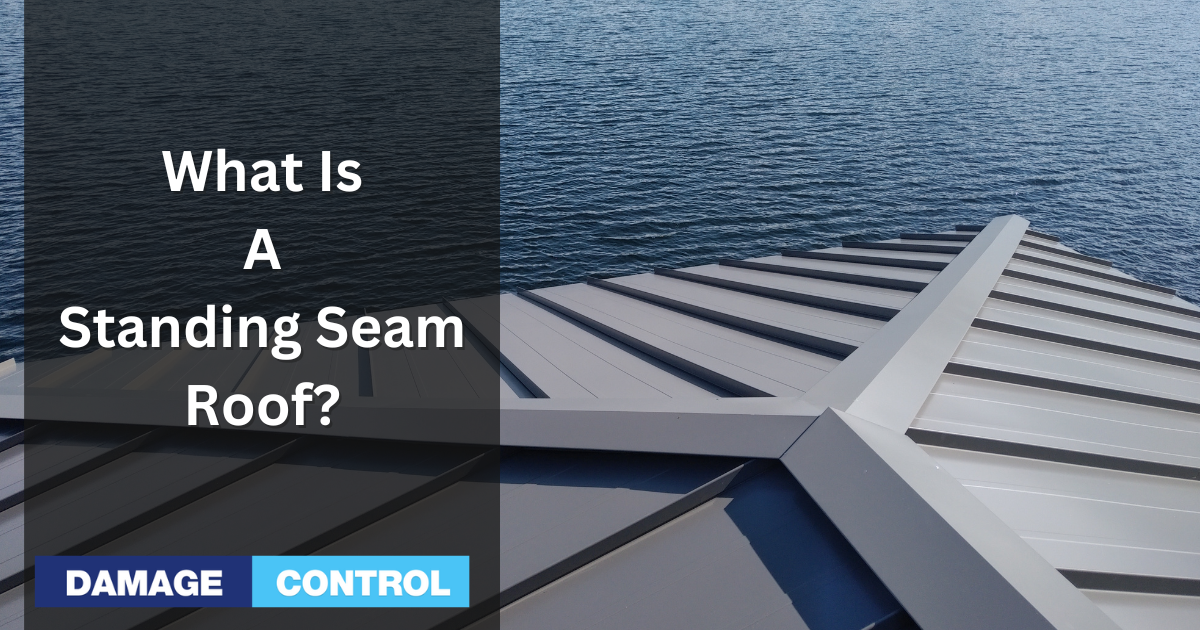

Welcome to our ultimate guide on standing seam metal roofs. You're about to embark on a journey that'll leave you with a wealth of knowledge on this fantastic roofing option.

So, what's the deal with standing seam metal roofs? They're a type of metal roofing system consisting of long, continuous metal panels running from the ridge down to the eaves. These panels interlock with one another via raised seams, hence the name “standing seam.”

With a history dating back to centuries, standing seam metal roofs have evolved from being a popular choice for agricultural and industrial buildings to become a sought-after option in modern architecture.

Stick around as we explore the benefits, installation process, and frequently asked questions about standing seam metal roofs. By the end, you'll be well-equipped to make an informed decision for your next roofing project!

Types of Standing Seam Metal Roofs

Before we dive into the benefits and installation process, it's crucial to know the different types of standing seam metal roofs available such as snaplock panels and fastening. Understanding the distinctions will help you choose the best option for your specific needs. So, let's take a closer look at the most common types.

Snap-lock

Snap-lock panels are like the superheroes of the standing seam world – they're quick, efficient, and reliable. As the name suggests, these metal panels come with a male and female leg that “snap” together, forming a secure connection. The installation is a breeze, making snap-lock a popular choice for residential and commercial projects.

Mechanical lock

Mechanical lock panels are the tough guys of standing seam metal roofs. They consist of two panels that require a special seaming tool to crimp and lock the seams together.

There are two subtypes: single-lock and double-lock systems. While the single-lock requires one fold, the double-lock system needs two folds for added durability. Mechanical lock panels are ideal for low-slope roofs and areas with extreme weather conditions.

Mechanical lock systems are commonly used on multi-story commercial buildings because of their extra strength and durability in high wind conditions. The higher the roofline, the higher winds the roofing system is subject to.

Batten panel

Batten panel systems, also known as “raised seam” or “high seam,” feature a unique design. They consist of metal panels separated by a batten, which is a thin strip of wood or metal.

This batten raises the seam, providing a distinctive aesthetic and improved structural performance. Batten panels are suitable for both traditional and contemporary architecture, giving you the flexibility to match your desired style.

Comparison of different types

Now that we've covered the various types of standing seam metal roofs, how do you choose the right one? It all comes down to factors like budget, slope, aesthetics, and weather conditions.

A snap-lock panel offers quick and easy installation, while a mechanical lock offers superior protection. Batten panels, on the other hand, combine visual appeal with structural strength. Weigh your options carefully, and you'll be on your way to a stunning new roof!

Benefits of Standing Seam Metal Roofs

Now that we've explored the different standing seam metal roof types, let's dive into their numerous benefits. From durability to energy efficiency, these roofs truly shine (pun intended) in many aspects.

Durability and longevity

One of the most significant advantages of standing seam metal roofs is their incredible durability. These roofs are made to last, with a lifespan ranging from 40 to 70 years! That's right, you can install a standing seam metal roof and forget about roof replacement for decades. Talk about a long-term investment!

Weather resistance

Mother Nature can be quite a force, but standing seam metal roofs stand strong against her challenges. These roofs are designed to resist heavy rain, hail, snow, and even high winds. Plus, the raised seams help prevent water infiltration, ensuring your home stays cozy and dry.

Energy efficiency

If you're looking for a solid and efficient roofing option, look no further. Standing seam metal roofs boast excellent energy efficiency, thanks to their reflective properties.

These roofs can bounce back sunlight, keeping your home cooler during the hot summer months. This means less strain on your AC and reduced energy bills. It's a win-win situation.

Low maintenance

Who doesn't love a low-maintenance roof? Standing seam metal roofs require minimal upkeep, which saves both time and money. These roofs are resistant to corrosion, algae, and moss, meaning you won't have to worry about frequent cleaning or repairs. You'll need a good gutter system to catch debris and safely get it to ground level.

Just an occasional inspection and rinse will keep your roof looking good as new.

Aesthetics and design flexibility

Last but not least, standing seam metal roofs offer unmatched design flexibility. These roofs come in a variety of materials, colors, and finishes, allowing you to create the perfect look for your home or building. Plus, the clean lines and sleek appearance of standing seam metal roofs can complement any architectural style, from traditional to modern.

There are also many different looks to standing seam roofing panels, which gives you more aesthetically pleasing options to choose from.

Let your creativity run wild. It's all in your hands.

Standing Seam Metal Roof Materials

As you consider a standing seam metal roof for your project, it's essential to understand the various material options available. Each material has its unique advantages and aesthetic appeal.

Let's delve into the most popular choices and compare them to help you make an informed decision.

Aluminum

Aluminum is a lightweight, corrosion-resistant material that's perfect for standing seam metal roofs. It's an excellent choice for coastal areas, as it can withstand the harsh effects of saltwater. Aluminum is not the best choice for multi-story buildings because of wind issues. Use steel on commercial buildings with high elevations for added strength.

Steel

Steel is a popular choice for standing seam metal roofs, thanks to its strength and affordability. It typically comes in two forms: galvanized and Galvalume. Galvanized steel is coated with zinc, while Galvalume is coated with an aluminum-zinc alloy, offering increased corrosion resistance.

Steel roofs are durable, budget-friendly, and available in a wide range of colors and finishes.

Copper

Copper is the luxury car of standing seam metal roof materials. With their natural beauty and exceptional durability, copper roofs make a statement. They are extremely beautiful when new, but copper develops a stunning green patina over time, adding to its visual appeal.

Fun fact: The patina covers the copper and protects it from the elements. Natural beauty at its best.

While it may be more expensive than other materials, copper's longevity and low maintenance make it a worthwhile investment, not counting the increase in value of the property for simply having a copper roof.

Zinc

Zinc is another high-quality metal option for standing seam roofs. It's corrosion-resistant, durable, and features a unique self-healing property. Scratches on zinc surfaces gradually disappear, as the metal forms a protective layer called zinc hydroxyl carbonate.

Zinc is another high-quality metal option for standing seam roofs. It's corrosion-resistant, durable, and features a unique self-healing property. Scratches on zinc surfaces gradually disappear, as the metal forms a protective layer called zinc hydroxyl carbonate.

Zinc roofs provide a modern, industrial aesthetic that's perfect for contemporary designs.

Zinc also kills algae and mold. With asphalt shingle roofs, small strips of zinc are placed at the ridge cap, and as rain falls and rolls across it, it spreads zinc across the roof, eliminating the algae and mold that grows on asphalt roofing shingles.

Since zinc has these amazing properties, you not only prohibit mold on the exterior surface but also on the bottom, preventing mold growth on the bottom of the panels, underlayment, and the surface of the decking.

Comparing material options

Each material for standing seam metal roofs has its pros and cons. Aluminum offers lightweight, corrosion-resistant properties, while steel is strong and budget-friendly.

Copper and zinc both provide high-end, long-lasting solutions with unique aesthetic appeal. Consider factors such as cost, longevity, maintenance, and design preferences when choosing the right material for your project.

Components of a Standing Seam Metal Roof System

To ensure a successful standing seam metal roof installation, it's essential to understand the key components involved. A well-designed system guarantees a visually appealing result and ensures the roof's longevity and performance. Let's take a closer look at these crucial elements.

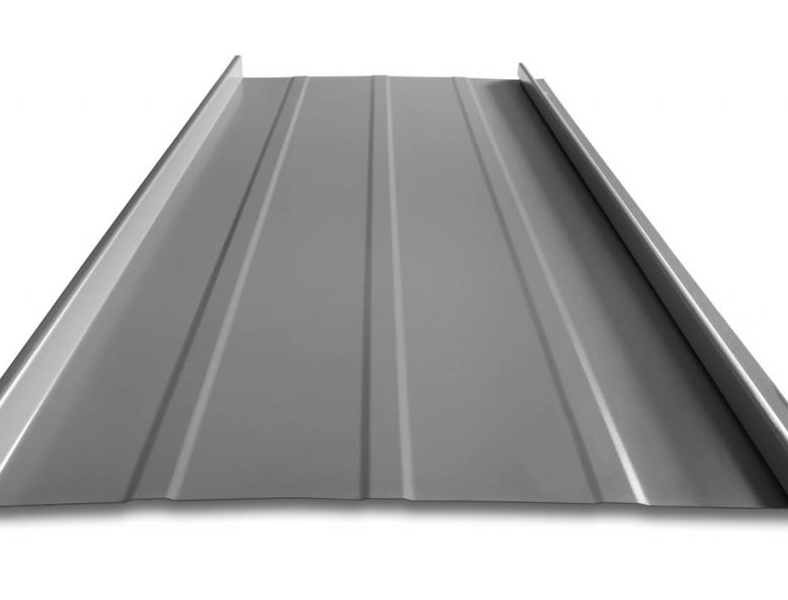

Roof panels

Roof panels are the backbone of a standing seam metal roof system. These long, continuous metal sheets run from the ridge to the eaves and interlock via raised seams. The panels can be made from various materials, such as aluminum, steel, copper, or zinc, and come in different styles, including snap-lock, mechanical lock, and batten panel.

Clips and fasteners

Clips and fasteners play a vital role in securing the metal panels to the roof deck. They ensure proper alignment and spacing, allowing the panels to expand and contract with temperature fluctuations. Clips and fasteners are designed to be concealed, maintaining the sleek appearance of the standing seam roof.

Underlayment

Underlayment is the unsung hero of a standing seam metal roof system. It's a protective layer installed between the roof deck and metal panels, providing an extra barrier against moisture, wind, and heat.

High-quality underlayment prevents leaks and enhances the roof's overall performance. This is one place you never cut corners. It's that important to your roof system.

Flashing and trim

Flashing and trim pieces are the finishing touches of a standing seam metal roof. They seal and protect vulnerable areas such as valleys, ridges, eaves, and penetrations like chimneys and vents. Proper flashing and trim installation is critical for preventing water infiltration and ensuring a watertight, durable roof.

Ventilation and insulation

A well-ventilated and insulated roof is key to maintaining a comfortable, energy-efficient home. Proper ventilation prevents heat buildup in the attic, reducing cooling costs and prolonging the life of your roof.

Insulation, on the other hand, helps regulate indoor temperatures and improves the overall energy efficiency of your home. Don't overlook these essential components when planning your standing seam metal roof project!

Installation Process and Best Practices

A successful standing seam metal roof installation requires careful planning, precision, and adherence to best practices. Whether you're a DIY enthusiast or working with a professional, understanding the process can help ensure a smooth, problem-free experience. Let's walk through the key steps involved.

Site preparation

The first step in any successful roofing project is proper site preparation. This includes clearing debris, trimming tree branches, and ensuring a clean working environment. Ensure all necessary tools, equipment, and materials are on hand to streamline the process.

Panel layout and measurements

Accurate measurements are crucial for a seamless installation. Begin by measuring the roof area and determining the panel lengths required. Carefully plan the panel layout, considering factors like seam locations, panel overlaps, and trim details. Remember, attention to detail now will save you headaches down the line!

The good news is most of the panels are made on-site now with mobile roll-forming machines, similar to how gutters are made, that make the panels as needed. These machines are very expensive, removing the possibility of taking the DIY route in most cases.

Unless you're a professional, standing seam is not a good idea for most DIY types.

Installing underlayment, clips, and panels

Once the site is prepared, and measurements are taken, it's time to install the underlayment. Roll it out, ensuring proper overlap and adherence to the roof deck.

Next, install the clips and fasteners according to the manufacturer's guidelines, maintaining consistent spacing for optimal performance.

Now you're ready to install the metal panels. Starting at one end of the roof, carefully align the first panel with the edge and secure it to the clips. Continue installing panels, making sure each one interlocks correctly with the previous one. Take your time and double-check your work to ensure a flawless result.

Proper flashing installation

Flashing is a critical component of a watertight standing seam metal roof. Install flashing at valleys, ridges, eaves, and around penetrations like chimneys and vents. Use high-quality sealant and fasteners to secure the flashing, ensuring a tight seal against water infiltration.

Final inspections

Once the installation is complete, perform a thorough inspection to check for any issues or inconsistencies. Ensure that all panels, flashing, and trim are correctly installed and secured. Address any concerns immediately to guarantee a long-lasting, high-performing standing seam metal roof.

By following these best practices and understanding the installation process, you'll be well on your way to a beautiful, durable, and energy-efficient standing seam metal roof.

Cost Considerations

As you contemplate a standing seam metal roof for your project, it's essential to consider the costs involved. From material expenses to labor fees, understanding the various factors will help you make an informed decision. Let's break down the key cost considerations.

Material costs

The cost of standing seam metal roofing materials varies depending on the type and quality of metal you choose. Aluminum and steel tend to be more affordable, while copper and zinc are on the higher end of the price spectrum. Additionally, the specific style and gauge of the standing seam system can impact the overall material cost.

Labor costs

Installing a standing seam metal roof requires skilled labor, which can add to the overall project cost. Labor rates vary based on factors like location, roof complexity, and the contractor's experience. It's essential to get multiple quotes and check references to find a reputable contractor who offers a fair price.

Hint: The lowest bid is not always the best choice, especially if the bid is significantly lower than others.

Long-term return on investment

While the upfront cost of a standing seam metal roof may be higher than some other roofing options, it's crucial to consider the long-term return on investment. With their exceptional durability, low maintenance, and energy efficiency, standing seam metal roofs can save you money over time. In many cases, the long-term benefits can offset the initial costs. Many homeowners increase the value of their homes, giving additional benefits.

Comparing costs with other roofing options

When weighing the costs of a standing seam metal roof against other options, comparing apples to apples is essential. Take into account factors like lifespan, maintenance requirements, and energy efficiency. While asphalt shingles may be less expensive upfront, they need to be replaced more frequently, potentially costing more in the long run.

By considering these cost factors, you can make an informed decision about whether a standing seam metal roof is the right choice for your project. Remember, it's crucial to weigh both the upfront costs and the long-term benefits to get a complete picture of the true value of your investment.

Maintenance and Repair Tips

Standing seam metal roofs are well-known for their low maintenance requirements. However, following some basic maintenance and repair tips is essential to ensure a long-lasting, high-performing roof. Let's explore the key practices to keep your roof looking and functioning at its best.

Regular inspections

Conducting regular roof inspections is crucial for detecting potential issues early. Schedule an inspection at least twice a year, ideally during spring and fall, to assess your roof's condition. Look for signs of damage, such as loose or damaged panels, and check the flashing and trim for any issues. Don't forget to inspect the gutters and downspouts to ensure proper drainage.

Cleaning and debris removal

Although standing seam metal roofs are resistant to algae and moss, keeping them clean is still essential. Remove debris like leaves, branches, and dirt to prevent water buildup and potential damage. Use a soft-bristle brush or a gentle (soft wash) pressure washer to clean your roof, taking care not to damage the panels or their protective coatings.

Do not use a high-pressure nozzle. You'll regret it if you do.

Repairing minor damages

If you discover minor damages during your inspection, address them promptly. For small scratches or paint chips, touch-up paint or a protective coating can be applied to prevent further damage. If a panel is severely dented or damaged, it may need to be replaced. Contact a professional for any repairs beyond your skill level.

When to replace a standing seam metal roof

A standing seam metal roof can last for decades with proper care and maintenance. However, there may come a time when replacement is necessary. If you notice widespread damage, corrosion, or extensive leaks, it could be a sign that your roof has reached the end of its lifespan. Consult with a professional to determine whether repair or replacement is the best course of action.

Choosing the Right Contractor

Selecting the right contractor is crucial for a successful standing seam metal roof installation. A skilled, reputable contractor can make all the difference in the final result and your overall satisfaction. Let's discuss the key factors to consider when choosing the perfect contractor for your project.

Research and referrals

Start by asking friends, family, and neighbors for referrals. Word-of-mouth recommendations can often lead you to trustworthy professionals. Additionally, conduct online research to read reviews, gather information on local contractors, and check their ratings with the Better Business Bureau.

Licensing and insurance

Before hiring a contractor, make sure they have the appropriate licensing and insurance. This protects you from potential liabilities and ensures the contractor adheres to industry standards and local regulations. Don't hesitate to ask for proof of licensing and insurance during your initial consultation.

Experience and portfolio

The experience and skill of your contractor play a significant role in the quality of your standing seam metal roof installation. Look for a contractor with a proven track record and a portfolio showcasing their previous work. A contractor experienced in standing seam metal roofs will be better equipped to handle the intricacies of the installation process.

Warranty and guarantees

A reputable contractor should stand behind their work and offer a warranty on both materials and labor. Make sure to discuss warranty details, including the coverage period and any exclusions. A solid warranty provides peace of mind, knowing that any potential issues will be addressed promptly and professionally.

Frequently Asked Questions

Let's address some common questions about standing seam metal roofs, which can help you decide whether this type of roofing is right for your project.

Can standing seam metal roofs be installed over existing roofs?

In some cases, standing seam metal roofs can be installed directly over existing roofs, such as asphalt shingles. This process, called “roof-over,” can save time and money by eliminating the need for tear-off and disposal. However, it's essential to consult with a professional to ensure the existing roof's structure can support the additional weight of the metal panels.

How much do standing seam metal roofs expand and contract?

Metal roofs naturally expand and contract due to temperature fluctuations. The extent of expansion and contraction depends on the type of metal and the roof's design. A properly installed standing seam metal roof system will accommodate this movement with concealed clips and fasteners, preventing damage or leaks.

Can I install solar panels on a standing seam metal roof?

Yes, you can install solar panels on a standing seam metal roof. In fact, standing seam roofs are well-suited for solar panel installations since they offer a secure, durable surface with minimal penetrations. Special clamps can be used to attach solar panels to the raised seams without drilling or damaging the roof.

Is a standing seam metal roof noisy during rain or hail?

While metal roofs can be noisier than some other roofing materials, proper insulation and underlayment can significantly reduce noise levels. A well-installed standing seam metal roof should not be excessively noisy during rain or hail.

How do I know if a standing seam metal roof is right for my home?

Determining whether a standing seam metal roof is right for your home depends on factors such as your budget, location, climate, and aesthetic preferences. Consider the advantages of a standing seam metal roof, such as durability, energy efficiency, low maintenance, and the costs and installation requirements.

Conclusion

Choosing a standing seam metal roof for your project involves weighing various factors, from aesthetics to costs and maintenance. By understanding the benefits, installation process, and key considerations, you can make a well-informed decision that suits your needs and preferences. A standing seam metal roof can be a long-lasting, beautiful, and energy-efficient addition to your home or building.